会社案内

会社理念

創造力によって未来を築き

モノづくりの喜びをお客様と共有する

技術者の集まりです。

会社設立の理念は社名にあります。

会社名はアルファベットでJUSTEMと書き、

お客様にJust FitするSystemを提供する

という意味を表します。

会社概要

| 商号 | 株式会社 ジャステム |

|---|---|

| 所在地 | 本社 〒940-2147 新潟県長岡市新陽1丁目15番地 TEL:0258-47-2571 FAX:0258-47-2572 |

| WEB | https://www.justem.jp/ |

| 設立 | 2005年(平成17年)6月 |

| 資本金 | 1,900万円 |

| 従業員 | 15名(令和3年9月現在) |

| 代表取締役 | 新保良成 |

| 取引銀行 | 第四北越銀行、日本政策金融公庫、大光銀行 |

本社社屋

アクセスマップ

社長挨拶

株式会社ジャステムはベンチャー企業として2005年に設立いたしました。

お客様や地元のみなさまからご指導・ご鞭撻を頂きながら、多くの装置を開発し納入することができました。

心より感謝申し上げます。

ジャステムの設立目的は社名にもなっている 「お客様にJust FitするSystemを提供する」ことです。

多くの装置メーカが利益を追求するあまり、手間やリスクのあるカスタマイズを避ける傾向にあります。

しかし、同じ企業でも工場が違えば、品質要求、生産量、人員、予算、など様々な条件が異なるのが実態です。それなのに、装置メーカーから競合他社と同じ装置を導入しても、大きな違いにはならず競争力にはなりません。

本当は生産現場にフィットした競合他社にはない「お客様だけの装置」を望まれているはずです。

その声にこたえ続けることがジャステムの使命であり、存在価値であると考えております。

これからも、ジャステムはその製造工程のプロフェッショナルであるお客様の声を真摯に受け止めて、

開発を続けます。そして多くのみなさまと「喜びを共有」できるように、技術の研鑽に努めてまいります。

微力ではありますが、地元や日本はもちろん、世界各国の産業発展に貢献できるよう、全力を尽くしてまいります。

今後とも、ご指導ご鞭撻のほど、よろしくお願い申し上げます。

会社沿革

~JUSTEMの生い立ちから現在まで~

| 1998年11月 | 新保良春 JTECH個人事業を開設 自動車部品加工装置、鋼管製造ライン等の設計製作、ISO規格のコンサルタント業務 |

|---|---|

| 2003年8月 | 社員を新規雇用、活動を拡大し、ラップ自動装填装置を受注 |

| 2003年9月 | 長岡リサーチコアインキュベーションセンター テクノプラザ内LABONAに移転、

装置開発設計と並行し電子部品製造を行う。 非接触厚さ測定機の受注・開発、転造盤の受注・納品 |

| 2005年6月 | 株式会社ジャステム設立 代表取締役社長 新保良春、資本金 1千万円、従業員 7名 |

| 2006年10月 | 株式会社第四キャピタルより900万円の出資を受け資本金1900万円に増資 |

| 2007年2月 | 新潟県工業技術総合研究所と共同で 次世代大口径シリコンウェーハ向け浮上式厚さ測定機(FTM)試作機を開発 |

| 2008年1月 | 第3期(08年1月期)で売上4億円達成 |

| 2008年4月 | 東京都町田市に東京営業所開設 |

| 2008年10月 | 体制を変更 代表取締役会長 新保良春、代表取締役社長 新保良成 事業拡大に伴い、長岡市新陽1-15(長岡オフィス・アルカディア)に新社屋を完成し移転。従業員数 18名 |

| 2009年4月 | 長岡市フロンティアチャレンジ補助金事業の認定を受け、「φ450mmウェーハ厚さ測定機」を開発 |

| 2010年4月 | 東京都中央区日本橋に東京営業所を移転 長岡市フロンティアチャレンジ補助金事業の認定を受け、「オプティカルセンサによる多種多層ウェーハ厚さ測定機」を開発 |

| 2011年4月 | 東京営業所を本社に統合 |

| 2012年6月 | 長岡市フロンティアチャレンジ補助金事業の認定を受け、「ウェーハ形状測定機」を開発本社工場内にクリーンルームが完成 |

| 2013年8月 | 経済産業省のものづくり支援事業の認定を受け、「透明体等ウェーハのキズ・パーティクル自動検査装置」を試作開発 |

| 2014年6月 | 長岡フロンティアチャレンジ補助金事業の認定を受け、「簡易面取り機」を開発 |

| 2015年1月 | 古物商許可証を取得(新潟県公安委員会第461190002281号) |

| 2016年12月 | 見本市等出展支援事業補助金の認定を受け、「SEMICON Japan 2016」へ初出展 |

| 2017年1月 | BOW/WARP測定機開発 |

| 2017年6月 | 日本酒試飲機3号機製作 |

| 2017年12月 | インライン用厚さ測定機製作 |

| 2018年1月 | 海外向け 外観検査装置製作 |

| 2018年6月 | ピーマン綿ぬき自動機製作 |

| 2018年8月 | 自動溶接 共同開発 |

| 2019年2月 | 顕微鏡ローダ開発 |

| 2019年5月 | 新素材向け厚さ測定機製作 |

| 2019年12月 | ウェハの製造プロセスにおける検査・試験装置に関する情報掲載をした専門サイト「ウェハ検査装置・測定装置ラボ.com」開設 |

| 2019年12月 | SEMICON Japan出展 |

| 2020年1月 | 生産技術エンジニア・設備エンジニア向けのウェハ検査に関するメールマガジン配信開始 |

| 2020年11月 | 非接触キャリア厚さ測定機開発 |

| 2021年3月 | 新素材向け厚さ仕分け装置開発 |

業務内容

■ 各種産業向け特注装置・専用装置の設計・製作 ■

半導体産業向け装置

- 工程管理用測定装置及び検査装置

- 製造工程内の自動化、省力化装置など

Siウェーハ以外に、SiCウェーハ等パワー半導体用の各種材料、LED基板用サファイアウェーハ、太陽電池、MEMS等の分野へ市場を拡大し、測定装置、検査装置の開発・納入を行っています。

その他産業向け装置

- 医薬関係検査装置

- 自動車産業検査装置、部品加工機

- その他専用機の開発・設計・製作・販売

各種材料 厚さ測定等のデモ測定

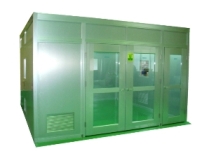

クリーンルーム(class1000)

[2012年7月完成]

シリコンウェーハはもちろん、SiC、サファイア等、各種材料の厚さデモ測定等承ります。

当社は、半導体業界が主力市場でありますが、業種を限定せず各種測定機・製造装置・合理化省力化装置そして検査装置や測定装置等の幅広い製造販売を行っております。

開発設計から製造販売までの範囲を少数精鋭で行っております。

現在までに70機種の製品開発に成功し、現状ではそれらのリピート受注と新規分野装置の開発に主力を注いでおります。

営業カレンダー

2024年

■休業日

| 日 | 月 | 火 | 水 | 木 | 金 | 土 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 14 | 15 | 16 | 17 | 18 | 19 | 20 |

| 21 | 22 | 23 | 24 | 25 | 26 | 27 |

| 28 | 29 | 30 | 31 |

| 日 | 月 | 火 | 水 | 木 | 金 | 土 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 11 | 12 | 13 | 14 | 15 | 16 | 17 |

| 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| 25 | 26 | 27 | 28 | 29 |

| 日 | 月 | 火 | 水 | 木 | 金 | 土 |

|---|---|---|---|---|---|---|

| 1 | 2 | |||||

| 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 17 | 18 | 19 | 20 | 21 | 22 | 23 |

| 24 | 25 | 26 | 27 | 28 | 29 | 30 |

| 31 |

| 日 | 月 | 火 | 水 | 木 | 金 | 土 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 14 | 15 | 16 | 17 | 18 | 19 | 20 |

| 21 | 22 | 23 | 24 | 25 | 26 | 27 |

| 28 | 29 | 30 |

| 日 | 月 | 火 | 水 | 木 | 金 | 土 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 29 | 30 | 31 |

| 日 | 月 | 火 | 水 | 木 | 金 | 土 |

|---|---|---|---|---|---|---|

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | 29 |

| 30 |

| 日 | 月 | 火 | 水 | 木 | 金 | 土 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 14 | 15 | 16 | 17 | 18 | 19 | 20 |

| 21 | 22 | 23 | 24 | 25 | 26 | 27 |

| 28 | 29 | 30 | 31 |

| 日 | 月 | 火 | 水 | 木 | 金 | 土 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 11 | 12 | 13 | 14 | 15 | 16 | 17 |

| 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| 25 | 26 | 27 | 28 | 29 | 30 | 31 |

| 日 | 月 | 火 | 水 | 木 | 金 | 土 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| 15 | 16 | 17 | 18 | 19 | 20 | 21 |

| 22 | 23 | 24 | 25 | 26 | 27 | 28 |

| 29 | 30 |

| 日 | 月 | 火 | 水 | 木 | 金 | 土 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| 20 | 21 | 22 | 23 | 24 | 25 | 26 |

| 27 | 28 | 29 | 30 | 31 |

| 日 | 月 | 火 | 水 | 木 | 金 | 土 |

|---|---|---|---|---|---|---|

| 1 | 2 | |||||

| 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 17 | 18 | 19 | 20 | 21 | 22 | 23 |

| 24 | 25 | 26 | 27 | 28 | 29 | 30 |

| 日 | 月 | 火 | 水 | 木 | 金 | 土 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| 15 | 16 | 17 | 18 | 19 | 20 | 21 |

| 22 | 23 | 24 | 25 | 26 | 27 | 28 |

| 29 | 30 | 31 |